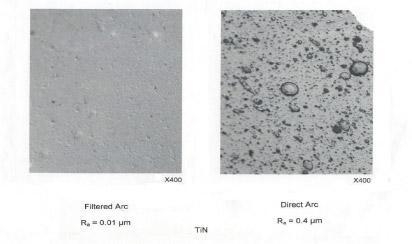

This is a real photo of our advanced filtered cathodic arc, it can deposit thin layer that own best properties.

Deep black ultra-hard DLC coating on watch parts

Mr. Liu

Shenzhen Kins Vacuum PVD coatings Ltd.

Mr. Liu

Shenzhen Kins Vacuum PVD coatings Ltd.

Why Rolex, Panerai,Seiko,Citizen,…so many famous watch brands use black DLC coating replacing traditional IP black?

DLC is Diamond-like Carbon. There are a few key characteristic of DLC, which has helped it to be used by Rolex,Panerai,Seiko,Citizen…

It's ultra hard

DLC is an extremely hard coating. The following graph shows the comparative surface hardness of various materials, using the Vickers of Hardness scale:

DLC is an extremely hard coating. The following graph shows the comparative surface hardness of various materials, using the Vickers of Hardness scale:

In terms of relative hardness, DLC, at 2000-5000 HV is: about 10X as hard as stainless stee, about equal to sapphire,about one-half as hard as diamond. Significantly harder than other PVD coatings (including IP black coating).

It's Extremely Wear Resistant

Because of its durability, DLC is used as tribological coating for machine tools such as drill bits, saws, and dies. When used on a watch, DLC coatings provide superior durability and high wear resistance.

It has a Lower Coefficient of Friction

DLC has very low coefficients of friction (about 0.01-0.1 compared to steel 0.7),So it’s quite slick. The following chart compares the coefficient of friction of DLC and other materials:

One of the primary uses of DLC is as a dry lubricant for machine parts, aerospace parts, F1 engine parts, bearings, ...even razor blades.

The low-friction attributes of DLC help to increase the durability of the coating when used on watches. Scratch or abrasion against a hard surface, which may dig in and damage normal PVD coating, are more likely to simply slide over across the surface of a DLC coated case.

Simply stated, it's just more difficult to damage a DLC coating.

The low-friction attributes of DLC help to increase the durability of the coating when used on watches. Scratch or abrasion against a hard surface, which may dig in and damage normal PVD coating, are more likely to simply slide over across the surface of a DLC coated case.

Simply stated, it's just more difficult to damage a DLC coating.

Most importantly, It has very high decorative

aesthetic value

Kins DLC coating can have very beautiful deep black color,maybe the blackest hard coating. Our deep black color is uniform,stable, consistent,even on every surface of 3D substrades,even on matt surfaces. Kins deep black color is very pure,without any rainbow color or any other color shadow. Kins deep black DLC coating is anti fingerprint and anti stick. It's corrosion resistant and

chemically inert, the deep black color is very stable, and anti-tarnish

. This color is very useful on high end products (like watches and jewellry parts) and it is widely welcomed by designers and consumers.

Why DLC were coated in Europe before?

DLC coating is a newly developed high technology. It need high tech plasma equipment and advanced process and professional technician. All these conditions are owned by western advanced countries a few years ago. Especially decorative high end watch parts are coated in Swiss,Germany…

What can Kins DLC coating bring to you?

Kins have been in vacuum plasma coating industry for more than ten years. We have cooperated with advanced organizations, invested on plasma equipments, developed some special high-tech processes. Now we supply excellent Kins DLC coating for our oversea customers for over one year. Kins DLC coating has following properties:

Thickness: 0.5-3micrometer, Hardness: 2000-5000HV, Coefficient of friction: 0.05-0.1, Color: deep black L#20-30, uniform,consistent,stable,pure on any surface of 3D substrates no matter matt or polished surface, anti fingerprints and anti stick, corrosion resistant and anti tarnish.

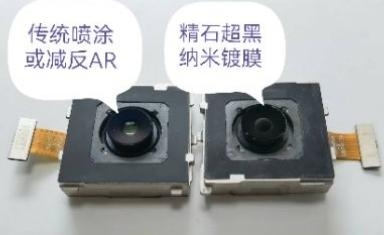

Why Kins deep black DLC is replacing PVD or IP black?

PVD IP black coating is a traditional black coating, it has been used for above ten years. Compared with kins DLC, PVD IP black is softer, rougher, poor wear resistant, easy to change color to yellowish,

nonuniform in color on 3D parts like watch cases, poor black degree with grey lightness(blackness #L over 40)

… In the contrary, Kins DLC is superhard, very tough, smooth, high wear resistant, stable, chemically inert, bio-

compatibile,anti fingerprint,non-sticky

,

and really beautiful consistent uniform pure deep black color, even on 3D parts! especially on matt surface!

It’s abvious, kins DLC black coating can completely

replace PVD IP black. No need to use IP black again from now!