Functional PVD hard coating: DLC coating on engine parts

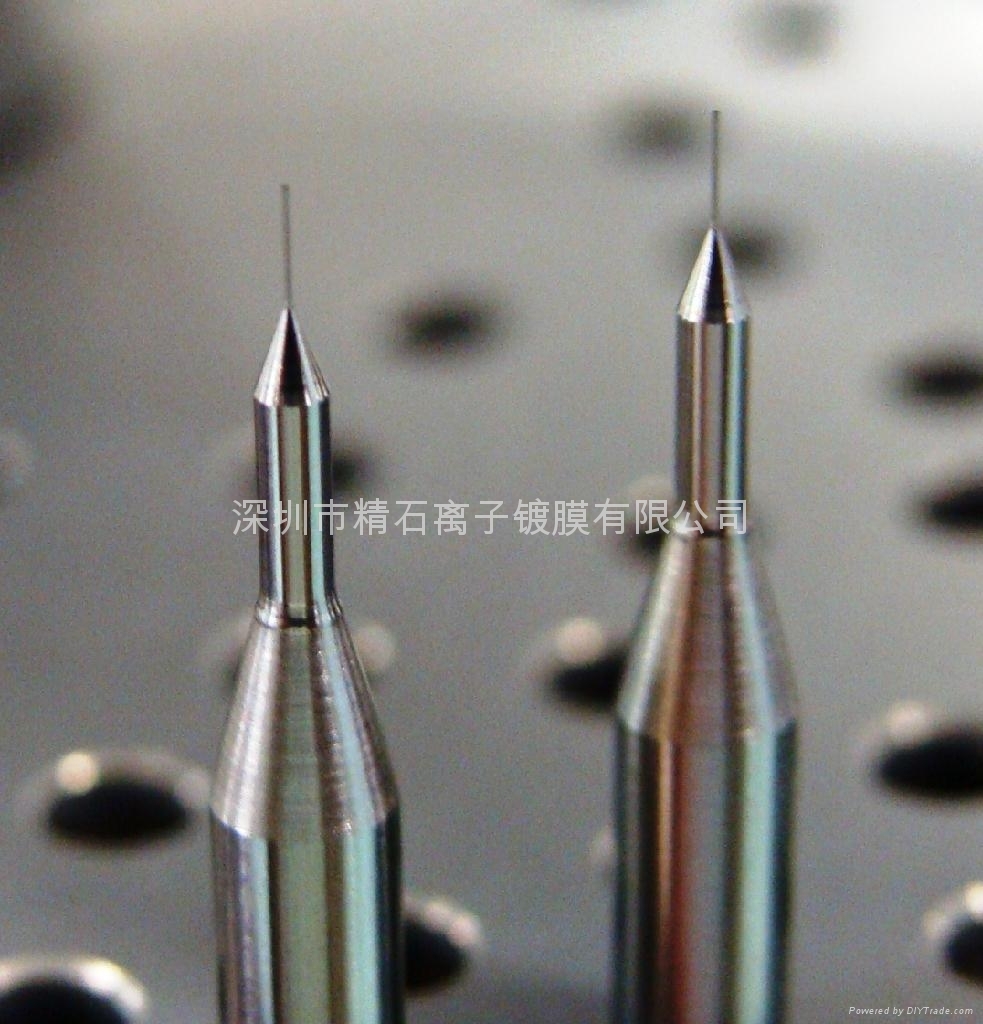

Functional PVD hard coating: on tools,molds,precision components

Functional PVD hard coating: on tools,molds,precision components

Functional PVD hard coating: on medical instruments parts

DLC low friction wear resistant hard coating

Functional PVD Hard Coatings

KinsPVD offers the latest in thin film coating and surface enhancement technology. Coatings are produced in a batch process under vacuum conditions. Elements such as titanium, chrome and aluminum are deposited by evaporation and magnetron sputtering techniques. Together with reactive gases such as nitrogen or acetylene these metals are deposited onto the surface of products in the vacuum chamber. Coatings are resistant for temperatures up to 2200?F/1200?C. Excellent adhesion and superb microstructure of these layers provide for extreme conditions of use. Process temperatures vary from 150?F/65?C to 340?F/170?C, depending on substrate materials and required purpose.

Advantage Applications

Extreme hardness provides prolonged lifetime Metalworking: cutting tools, drills,

of tools in abrasive circumstances saw blades, cold deformation and bending tools

The sticking effect of steel and non-ferrous

metals is minimized, resulting in higher uptime Automotive engine part: gears, sprockets,

piston rings, shafts, diesel injector pins,

Having a lower friction coefficient, production engine valves

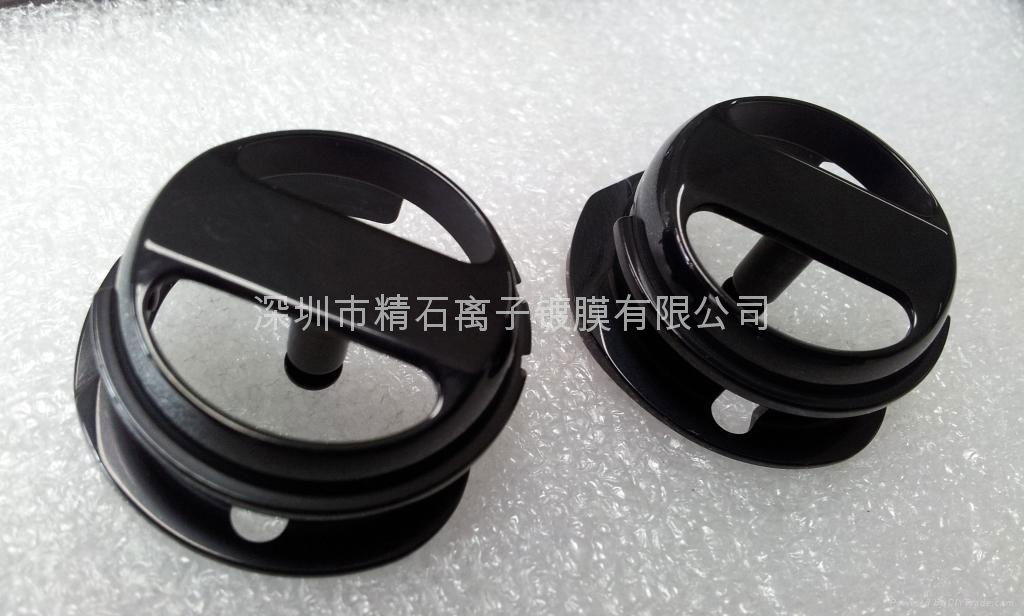

output can be increased dramatically Plastics and rubber processing: molds and dies

Tribological coatings such as metal-carbon coatings

open up new applications and provide Injection and extrusion molding (plastics and

added value to your product aluminum mold inserts, rotating cores, slides

and ejector pins

Through our extensive experience, you save Aircraft and space-industry: flap actuators

time and money in selecting the proper coating

for your application Medical tools and implants

Flexibility in choice of substrates Machine parts

Economies of scale

Physical Vapor Deposition is prevalent in many of the products that we use in our every day lives, from the semiconductors in our cell phones to the computer or lens of a space telescope. For some parts, PVD coatings serve to improve functionality and extend product lifetime, while other parts are PVD coated for decorative purposes. Listed below are some of the more common fields that utilize PVD coating extensively.

- Medical

- Aviation

- Automotive

- Electrically Conductive Films

- Optical Films

- Tribological and Tooling

Tribological and Tooling

The demand for high quality tribological coatings has led in recent years to intensive research into further development of the carbon based and/or multi-element and multi-layered coating complex. The PVD coatings are frequently used in order to improve the tribological performance of forming tools, cutting tools, and machine elements. Tribological performance of the coating of the tooling and moving part(s) are often characterized by the wear, abrasion, erosion and corrosion resistance properties of the coating. In all these applications the surface roughness of the coated part is of utmost importance since it will affect the friction, wear, and fatigue characteristics of the tribo- system.

Many of these PVD coatings are significantly harder than the substrate material that it's being deposited upon; a high coating surface roughness will result in a high wear rate of the substrate surface. In general, a high friction coefficient due to the protruding surface asperities (macro-particles, etc.) of the harder coating will wear against the softer substrate surface that it is supposed to protect. Further, a rough coating surface will also increase the material pick-up tendency which may cause problems such as galling in, e.g. metal forming applications. More importantly, the surface finish plays an essential role with the ultimate coating adhesion, which causes premature coating peeling. In order to reduce these problems, multi-layer coating systems are common, while intermediate layers are used to reduce internal stress and fatigue which also contribute to poor coating adhesion. These coatings are more versatile to the various substrate surfaces and exhibits improved adhesion and coefficient of friction by altering the matrix of the coating complex.

Medical

Since it was introduced to the medical device industry in the late 1980's, physical vapor deposition (PVD) has become widely used to deposit wear-resistant thin-film coatings on a variety of medical devices including orthopedic implants, pacemakers, surgical instruments, orthodontic appliances, and dental instruments. The value of PVD technology rests in its ability to modify the surface of properties of a device without changing the underlying material properties and biomechanical functionality.

PVD coatings provide a number of benefits to medical devices in addition to hardness and adhesion.

The most significant are as follows:

- Improved wear resistance

- Reduced friction

- Biocompatability

- Chemical barrier

- Decorative colors and aesthetic

Titanium and titanium based alloys such as Ti6Al4V have three important properties that are essential to medical, military and any other fields/industries that require low weight, rigid mechanical properties and chemical stability. Therefore companies have diverted tremendous effort into further research and development of these materials. The medical industries has ubiquitously found as tools temporal implants (as in osteosynthesis plate) and permanent implants (such as bone and dental replacements). However, acidity in the mouth and sterilization environments can vary greatly from near neutral to strongly acidic and/or basic sometimes reach both extremes of the pH scale. On both extreme of the pH scale, titanium and titanium alloys shows increased corrosion which leads to reduction in the lifetime of the implants in addition to releasing dangerous amount of titanium into the human body.

PVD coatings such as TiN, ZrN, CrN, DLC has been deposited onto titanium and titanium alloy surface are some of the surface treatment methods that are been both research and commercially adapted to improve corrosion resistance in both highly acidic and basic environment. In the recent academic research, Niobium/Niobium-Titanium based nitride coating deposition on titanium for corrosion protection of dental implants has shown to be a promising technique. The protective property increases as varying parameters of the Argon plasma during conventional sputtering deposition which in turn improves intermediate bonding layers and the coating structural interfaces. However this method compromised deposition rate which is an essential design criteria within a commercial setting. Arc Deposition on the other hand as the research shown is capable of much higher deposition rate in addition to the favorable deposition

Aviation

NASA pioneered the use of vacuum-deposited thin film solid lubricants. The lubricants are of two types: the low-shear metal lubricants, such as silver and lead, and the laminar-shearing compound materials-such as molybdenum disulfide (MoS2). The low-shear metal lubricants are usd in high-torque applications such as the rotating anodes in X-ray tubes. Low-shear compound materials are used in mechanical bearing applications in vacuum and where lubricant "creep" can be a problem. Because only a very thin film is needed for lubrication, the application of metal-containing carbon (Me-C) are used to reduce wear in mechanical contact applications.**

Automotive

In recent years the importance of fuel economy has become ever more important due to rising energy costs. Consequently, the major automotive companies have increased their focus on weight reduction and energy loss due to friction. These factors are two of the most important problems in motor-sports and it should be noted that sports such as Formula 1, where unit cost is less important than performance improvement, were the first to look at PVD coatings as an alternative to the traditional hard chrome.

In addition to performance enhancement, PVD coating can also be applied to the decorative aspect of automotives. In 1987, Cadillac developed the first gold trim program with the goal of providing a durable and consistently engineered finish for its customers. Since then, there have been more advancements in the PVD industry, such as the coating of ABS plastic, and other "un-coatable" material, in yesterday's standard. Looking into the crystal ball, one sees a bright future for PVD coating. The process offers many exciting prospects for new coatings of both color and performance.

Surface treatments used in daily manufacturing of parts for the automotive industry are selected to serve functional and decorative requirements achieved by mass production. Increased loads (mechanical, thermal, etc.), longer lifetime, weight reduction, friction reduction, and corrosion resistance are demanded for modern automotive systems. These demands are driven by depleting fossil fuel resources, economic competitiveness and environmental concerns, and have compelled exploration into new avenues to improve efficiency of automotive engines. Several classes of coating and alternative materials have been explored in the past decades and many more are currently researched. The motivation behind this research is to allow engines to operate at high temperatures with reduced external cooling. The reduction in engine weight to improve fuel efficiency has been partially realized by replacing the conventional cast iron engine blocks with aluminum-silicon crankcases.

More and more, surface enhancement engineering solutions are becoming the goal of the automotive industry in reduction of wear, friction and corrosion for powertrain parts and engine interiors. These engineered coatings are also applied for interior and exterior decoration. However, inadequate wear resistance and low seizure loads have prevented the traditional surface enhancement methods direct usage in the cylinder bores. The cylinder bore/piston and piston ring friction constitute nearly all of the piston system? friction losses. A major portion of oil consumption arises from bore distortion and poor piston ring sealing resulting from ring and bore wear. It could also be caused by the start of ignition where oil has not spread over entire surface.

Low friction coating in an internal combustion (IC) engine is an ideal feature that significantly helps the engine's fuel economy. The major sources of friction are valve train, piston system, and crank and bearing systems. The piston system accounts for 50-65% of the total friction loss, while valve train contributes to 10-20%. Crank and bear systems contribute considerably less.

Corrosion Resistance

Engine components are subject to severe chemical corrosion from engine oil, lubricant, and other combustion residues. The high temperature cycles would sometimes cause diesel engine and internal combustion (IC) engines to produces sulfuric and formic acid under certain conditions.

Wear resistance/Tribological property Coatings have been applied to improve the wear resistance of the Aluminum engine parts, placing them on a comparable level to their cast iron counter part.

Heat transfer/insulation Heat transfer to the block is kept to an absolute minimum, since this represents heat loss, this is done through a class of coating known as Thermal Barrier Coating (TBC). In the case of cooling components where heat transfer is preferred, inclusive research has been done to explore the option.

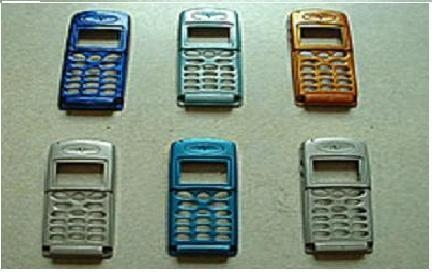

Electrically Conductive Films

The most common electrical conductors are metal films. Metal films may be used as "blanket" metalization or can be formed into discrete conductor lines ("stripes") by making the substrate during deposition or by subsequent photolithographic etching processes. Conductor lines are used in hybrid microcircuit technology and in the manufacture of semiconductor devices. Often, the electrical conductors are multi-layer films (stacks) where each layer has a function. For example, the conductor film stack might have the following composition: glass-Ti-Pd-Cu-Au. The titanium (Ti) is the "glue" layer, the palladium (Pd) provides corrosion resistance, the copper (Cu) is an electrical conductor, and the gold (Au) provides corrosion protection. Deposited metal conductors in "vias" are used in establishing electrical contacts between different layers in semiconductor device manufacturing. Blanket metallization is used to provide electromagnetic interference (EMI) and radio frequency interference (RFI) shielding on structures such as the plastic cases for cellular phones, electrodes for rigid and flexible capacitor electrodes, and surfaces for radar "chaff".

Metal nitride, carbide, and silicide films generally are electrically conductive (Si3N4 and AlN are important exceptions). In some applications, films of these refractory materials are used to provide diffusion barriers between materials. For example, in semiconductor metallization, aluminum or gold electrode material will diffuse into the silicon during high-temperature processing. An electrically conductive titanium nitride film deposited on the silicon surface before the metal electrode is deposited will prevent the diffusion. Generating stable, compounds is an important and aspect of semiconductor device fabrication. Metal nitrides such as tantalum nitride (TaN) are used as thin film resistor materials. Non-transparent electrically conductive oxides such as chromium trioxide (Cr2O3), lead oxide (PbO), and ruthenium oxygen (RuO) are used as electrodes in high-temperature oxidizing atmospheres.**

Optical Films

Optical films, usually multilayer films ("stacks"), are films that affect the optical transmission or reflection of a surface. They are generally alternating layers of materials having high germanium (GE), Si, TiO2, zirconium dixoide (ZRO2), SiO, cerium dioxide (Ce)2), and low magnesium fluoride (MgF2), SiO2 indices of refraction. A major application is the antireflection (AR) coatings on lenses. Optical film stacks can be used as optical filters. Neutral density or gray filters reduce the light intensity for all wavelengths: broadband filters affect the transmission of radiation over a wide wavelength range, while narrow or monochromatic filters affect transmission over a very narrow wavelength region. An example of a broadband filter is an "edge filter" that "cuts off" the ultraviolet (UV) emitted by a mercury vapor lamp. Examples of narrow-band filters are the color filters used in photography and in projectors.

Decorative Hard PVD coatings:staineless steel high-end consumer goods

| Pure white or black ceramics are widely used in watch parts. But the traditional surface finishing is very difficult. At first you can only coat the links or grains by PVD ion plating, then make up the links to a complete bands, it's very expensive and time-wasting and the wastage rate is high. Now using Kins PVD unique technology, we can IP the whole watch bands which have ceramics links and stainless steel links in gold color or two tone colors. The new technology is cheap,quick, has no wastage. |

Decorative PVD coatings combine certain functional aspects with an aesthetically pleasing visual appearance. Now vastly preferred over plating, PVD coatings ensure high volumes,fewer rejections and product stability unsurpassed in the decorative industry. This highly specialized, environmentally friendly PVD process occurs inside a vacuum chamber

where nitrogen, zirconium or other metal ions condense and adhere to a chrome plated plastic or metal substrate forming a thin, hard coating. This creates a layer of protection that provides longer lasting resistance to wear and tear of everyday use, and at the same time delivers attractive more durable finish than alternative processes. We offer standard and custom colors with uniform deposition. These coatings are ultra hard and resist cracking and chipping, thus maintaining their beauty under stress of everyday wear and tear.

Advantage Applications

Extremely high wear resistance due to high Sanitary fittings and accessories

hardness (>2000 HV) Architectural hardware

Wide choice of colors Nautical hardware

Superior appearance leading to high Domestic appliances

quality image Automotive interior and exterior parts

Very high color uniformity from batch to batch Telecom and computer casings

Flexibility through possibility of mixed loads Law enforcement and military equipment

Original surface condition maintained after Blades and knives

PVD processing Sporting goods and equipment

Flexibility in choice of substrates Special gifts

Economies of scale Handguns and rifles

Decorative Hard PVD coatings

Decorative Hard PVD coatings

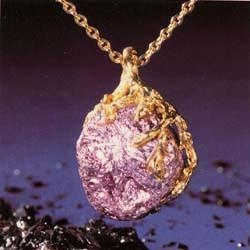

Gemstomes (topaz,crystals,agate,quartz...) plating gold , blue color , purple color, black color, coffee color, rainbow......

Gemstomes(topaz,crystals,agate,quartz...) plating gold, blue color , purple color, black color, rainbow...

PVD Coating is the coating process used by the leading designers and manufacturers in business today. Our finishes provide protection up to a lifetime抯 worth of cleaning, abrasives, daily use and abuse and still remain untarnished and vibrant.

Some of the Attributes Gained from PVD Coating are:

- Corrosion Resistance

- Scratch Resistance

- Superior Wear Resistance

- Higher Hardness Rating

- Superior Adhesion Qualities

- A Wide Range of Colors and Shades

- Provides a High-Rated Finish that lasts a Lifetime

PVD Coating has been used as a finishing for many years, dating back to the late 1800s. It offers corrosion and wear resistance far superior to electro-finishing, though due to the low melting points of the substrates, electro-plating is an important pre-treatment process to decorative PVD Coating.

Decorative PVD Coating enhances the visual and functional performance of your product. The thin film provides a dense and adherent protective 搒kin?on your product, reducing the number of dissatisfied customers, and providing added benefit to the consumer.

PVD Coating will not dull or enhance the appearance of the substrate it is applied to; i.e. if a coating is applied to a mirror finish, then polishing is required, but the coating will retain the mirror finish.

Here are some Facts about Decorative PVD films:

- Films are crystalline-like structures, with a hardness rating equivalent to coating tools.

- Films do not require clear organic topcoats since they have no solar degradation.

- Films produce superior cycle to cycle color replication.

- Films are colorfast over time and surprisingly affordable.

Materials that Can Be Coated

- Steel

- Stainless Steel

- Brass

- Aluminum

- Aluminum Alloys

- Magnesium Alloys

- ABS Plastics

- Copper

- Titanium

- Many others, please Inquire!

Available Colors

- Bronze

- Gold

- Brass

- Matte

- Chrome

- Matte Copper

- Satin Copper

- Spectrum

- Chameleon

- Platinum Gold

- Sapphire Blue

- Purple

- Matt Gold

- Satin Pale Gold

- Satin

- Copper